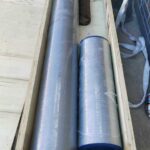

The main specifications of stainless steel hollow bar are as follows:

I. Size Range

Outer Diameter (OD): Typically ranges from 32mm (1.26 inches) to 420mm (16.5 inches). For example, some sizes may include combinations such as 32/16mm, 36/25mm, and 40/28mm, where the first digit represents the outer diameter and the second represents the inner diameter.

Inner Diameter (ID): Matches the outer diameter, offering a variety of options to meet different application requirements. For example, a hollow bar with an outer diameter of 32mm may have an inner diameter of 16mm, 20mm, and so on.

Length: Available in random, fixed, or cut lengths. Random lengths typically range from 2.5 meters to 6.5 meters, depending on size and grade. Fixed or cut lengths are custom-made based on customer requirements.

II. Materials and Grades

Stainless steel grades include: 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, and F51. These grades offer varying corrosion resistance, mechanical properties, and processing characteristics to meet various application requirements.

III. Manufacturing Standards

ASTM standards, such as ASTM A276, A479, and A484, specify the chemical composition, mechanical properties, and dimensional tolerances of stainless steel hollow bar. Other standards: ASME SA A276 and A479, as well as international standards such as JIS G4303, JIS G4311, DIN 1654-5, and DIN 17440, may also be used in the manufacture and inspection of stainless steel hollow bar.

IV. Manufacturing Process

Seamless Manufacturing: Stainless steel hollow bar is typically manufactured using a seamless process, ensuring a continuous and uniform structure without any welded joints. This enhances its strength and eliminates the risk of weak points.

Surface Treatment: Depending on customer requirements, stainless steel hollow bar can undergo a variety of surface treatments, such as polishing, pickling, and grinding, to improve its appearance and corrosion resistance.

V. Applications

Engineering and Manufacturing: Stainless steel hollow bar is widely used in various engineering and manufacturing fields due to its high strength, lightweight, and corrosion resistance. For example, in the aerospace industry, it can be used to manufacture lightweight structural parts; in the medical device industry, it can be used to manufacture corrosion-resistant instruments and components.

Construction and Infrastructure: Stainless steel hollow bar is also commonly used in the construction and infrastructure sectors, such as bridges and building support structures. Their corrosion resistance and high strength enable them to maintain stable performance for a long time in harsh environments.