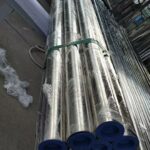

The Ultimate Guide to Stainless Steel Pipes with Precision Polished Inside and Outside

Stainless steel pipes are ubiquitous in various industries, from plumbing to automotive, and for good reason. They offer exceptional durability, corrosion resistance, and a sleek appearance. But not all stainless steel pipes are created equal. Today, we’re diving deep into the world of stainless steel pipes that boast precision polishing both inside and outside. Let’s explore what sets them apart and why they might be the perfect fit for your next project.

What is Precision Polishing?

Precision polishing is a process that smooths the surface of the stainless steel to a high luster, both on the inside and the outside of the pipe. This isn’t just for aesthetics; it serves several crucial functions:

Enhanced Corrosion Resistance: A polished surface reduces the likelihood of corrosion. The smoother the surface, the fewer pockets for corrosive agents to hide.

Improved Cleanliness: For industries like food and beverage, pharmaceuticals, or medical devices, a polished pipe ensures no contaminants adhere to the surface, making it easier to clean and maintain sanitation.

Better Flow Characteristics: In fluid dynamics, a smoother interior surface reduces friction and turbulence, leading to more efficient flow rates.

Aesthetic Appeal: A high-gloss finish is not only visually appealing but also indicates a high standard of quality and craftsmanship.

The Manufacturing Process

Creating a stainless steel pipe with precision-polished surfaces involves several meticulous steps:

Material Selection: High-grade stainless steel is chosen for its inherent corrosion resistance and durability.

Pipe Formation: The stainless steel is formed into pipes using processes like seamless or welded techniques.

Initial Grinding: Coarse grinding removes larger imperfections and prepares the surface for finer polishing.

Fine Polishing: Multiple stages of polishing with progressively finer abrasives achieve the mirror-like finish.

Inspection: Each pipe undergoes rigorous inspection to ensure it meets the required standards for surface finish and dimensional accuracy.

Applications

The versatility of precision-polished stainless steel pipes makes them suitable for a wide range of applications:

Food and Beverage Industry: Used in production lines for liquids like milk, beer, and soft drinks where cleanliness is paramount.

Pharmaceuticals: Essential in environments where contamination must be minimized.

Automotive and Aerospace: Utilized in systems where fluid dynamics and resistance to extreme conditions are critical.

Architectural and Decorative Uses: Their sleek appearance makes them a favorite for modern architectural designs and interior decor.

Why Choose Precision-Polished Stainless Steel Pipes?

Opting for stainless steel pipes with precision polishing both inside and outside offers numerous advantages:

Longevity: These pipes last longer due to their resistance to corrosion and wear.

Low Maintenance: The smooth surface is easy to clean and maintain, reducing downtime and maintenance costs.

Performance: Enhanced flow characteristics and reliability in demanding environments.

Value: Though they may come at a higher initial cost, the long-term benefits and reduced need for replacements offer significant savings.

Conclusion

Investing in stainless steel pipes with precision-polished inside and outside surfaces is a decision that pays off in durability, performance, and aesthetics. Whether you’re in an industry that demands the highest standards of hygiene, efficiency, or visual appeal, these pipes are a superior choice.

If you’re considering these pipes for your next project, ensure you source them from a reputable manufacturer who adheres to strict quality control measures. The difference will be evident in the performance and longevity of your application.