Stainless steel pipe cutting -value added services

In modern industry and manufacturing, stainless steel pipe is widely used across various industries due to its excellent corrosion resistance, high strength, and good machinability. From construction and automotive to medical equipment, stainless steel pipe is ubiquitous. As market demands diversify, pipe cutting services are becoming increasingly popular for many companies to meet specific length and shape requirements. This article will explore the importance and applications of stainless steel pipe and similar pipe cutting services, drawing on practical applications.

The Wide Range of Stainless Steel Pipe Applications

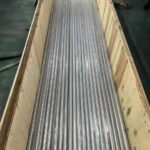

Stainless steel pipe comes in a variety of forms, the most common being seamless and welded pipe. They not only excel in structural applications but also play a vital role in fluid transport, heat exchangers, and equipment manufacturing for the chemical, food, and pharmaceutical industries. For example, the small sections of stainless steel pipe shown in Figures 1 and 2, after cutting and processing, can be used in the manufacture of precision instruments, while the long stainless steel rods (or tubes) shown in Figure 3 are often used in construction or large-scale equipment.

The Importance of Pipe Cutting Services

Due to the wide range of applications for stainless steel pipe, the size and shape requirements vary across industries. Pipe cutting services have evolved precisely to meet these diverse needs. Through precise cutting technology, stainless steel pipes can be cut into specific lengths and shapes according to customer requirements, thereby enhancing the product’s suitability and added value.

Technology and Equipment for Pipe Cutting Services

Modern pipe cutting services rely on advanced cutting technology and equipment. Common cutting methods include mechanical cutting, laser cutting, and water jet cutting. Mechanical cutting is suitable for general cutting needs, offering low cost and high efficiency. Laser cutting is popular for its high precision and wide applicability, making it particularly suitable for precision machining. Water jet cutting, with its cold cutting properties, avoids thermal deformation of the material during the cutting process, making it suitable for applications requiring high-quality cut edges.

Application Examples of Pipe Cutting Services

In practice, pipe cutting services have been successfully applied in various fields. For example, in automotive manufacturing, stainless steel pipes need to be cut to specific lengths and angles to meet the manufacturing requirements of components such as exhaust pipes and fuel lines. In the construction industry, cut stainless steel pipes are used to install components such as handrails and decorative strips. In medical device manufacturing, precision-cut stainless steel pipes are essential components of many devices.

Future Outlook

With technological advancements and evolving market demands, stainless steel pipes and pipe cutting services will usher in new development opportunities. The widespread adoption of intelligent cutting equipment will further improve cutting precision and efficiency, meeting more complex and personalized needs. Furthermore, environmental protection and sustainable development will drive innovation in cutting technology, reducing waste and energy consumption.

Conclusion

Stainless steel pipe and similar pipe cutting services play an indispensable role in modern industry. Through precise cutting and processing, the application range of stainless steel pipe has greatly expanded, meeting the diverse needs of various industries. In the future, as technology continues to advance, pipe cutting services will continue to play a vital role, providing more efficient and environmentally friendly solutions for industrial manufacturing.