Wenzhou Walmi Stainless Steel Co., Ltd.: Crafting High-Quality Stainless Steel Perforated plates with Ingenious Craftsmanship

In architectural decoration and industrial manufacturing, stainless steel perforated plates are becoming the material of choice for designers and engineers due to their unique visual aesthetic and functionality. As a leading company in the industry, Wenzhou Walmi Stainless Steel Co., Ltd. showcases its superior manufacturing capabilities and innovative application concepts in stainless steel perforated plates through three sets of live photos of customized products that will soon be shipped.

Precision Craftsmanship Achieves Exceptional Quality

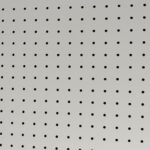

The three batches of stainless steel perforated plates shipped this time all utilize a 304 food-grade stainless steel substrate and are manufactured using a precision laser perforation process. The photos show three typical process characteristics:

The basic rectangular plates (Figure 1) feature a matte gray coating. The 2.5mm-diameter circular holes are evenly distributed, with a strictly controlled 3mm spacing between the holes. This ensures ventilation and light transmission while also enhancing weather resistance through the coating. They are suitable for high-traffic applications such as shopping mall curtain walls and airport soundproofing. The geometric cut version (Figure 2) features an innovative X-shaped beveled design, creating a visual contrast between the gray and perforated areas. This asymmetrical design enhances decorative appeal while optimizing localized sound absorption by varying the hole density. It is particularly suitable for acoustically sensitive venues such as concert halls and recording studios.

The industrial-grade polished version (Figure 3) features a mirror-polished finish with a surface roughness of Ra0.8μm and burr-free perforated edges. It can be directly used in filter components for food processing equipment or laboratory fume hood plates, meeting GMP certification standards.

Full-Scenario Application Solutions

Walmi’s core advantage lies in its “functional customization + adaptability to specific scenarios.” In the architectural field, its products have been successfully applied to the facade decoration of the Shanghai Tower and the sound insulation of the Hangzhou Asian Games venues. In the industrial field, the dust-proof ventilation plates customized for CATL’s new energy production line increase dust filtration efficiency by 40% through optimized hole patterns. In the commercial display field, the modular perforated display racks developed in collaboration with IKEA perfectly combine quick assembly with excellent light transmission.

Green Intelligent Manufacturing Leads the Industry’s Future

As a nationally recognized green factory, Walmi utilizes water-based paint and a circulating water cutting system in its production process, resulting in energy consumption per unit product that is 15% lower than the industry average. The company’s German TRUMPF laser cutting units and online inspection systems ensure that each batch of products has an aperture tolerance of no more than 0.05mm, and the surface treatment layer adhesion meets ASTM D3359 standards.

From artistic decoration to industrial manufacturing, from single functions to intelligent integration, Wenzhou Walmi Stainless Steel Co., Ltd. is redefining the application boundaries of stainless steel perforated sheet through technological innovation. These three sets of products, soon to be shipped worldwide, are not only a testament to the company’s strength but also a vivid illustration of China’s intelligent manufacturing taking the world by storm.