Wenzhou Walmi Stainless Steel Seamless Pipe: The “All-Round Warrior” of Industrial Pipelines, Building Trust with Quality

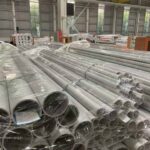

In the field of industrial pipelines, stainless steel seamless pipes, with their superior corrosion resistance, high strength, and long service life, have become the “golden choice” for industries such as petroleum, chemical, food, and medical. As the core product of Wenzhou Walmi Stainless Steel Co., Ltd., our stainless steel seamless pipes, with their comprehensive material coverage, ultra-wide specification range, and ultimate process standards, have become the preferred choice for customers worldwide.

Material Matrix: From Conventional to Specialty, Meeting All Scenarios Walmi stainless steel seamless pipes cover mainstream and specialty materials such as 304, 304L, 316L, 321, 310S, 2205, 2507, and 904L. Each material undergoes rigorous selection and process optimization:

General-Purpose Materials: 304/304L are suitable for scenarios with extremely high hygiene requirements, such as food processing and medical devices; 316L, with its stronger resistance to chloride ion corrosion, has become the “standard” for marine engineering and chemical equipment.

Specialty Materials: 321 contains titanium as a stabilizing element, offering excellent resistance to intergranular corrosion; 310S boasts outstanding high-temperature resistance, suitable for high-temperature environments such as boilers and heat exchangers; duplex steel 2205/2507 combines the advantages of austenitic and ferritic materials, offering superior strength and corrosion resistance; 904L is specifically designed for extreme corrosive environments, such as strong acids like sulfuric acid and phosphoric acid.

Flexible Specifications: From “Microtubes” to “Giant Tubes,” Precise and Controllable Dimensions

Our seamless tubes cover outer diameters from 10-920mm and wall thicknesses from 0.5-100mm, meeting diverse needs from precision instruments to large-scale projects. Each tube undergoes precision cold rolling/cold drawing processes, ensuring outer diameter tolerance ≤ ±0.1mm, wall thickness tolerance ≤ ±5%, and straightness ≤ 1mm/m, far exceeding industry standards.

Craftsmanship and Ingenuity: From the Inside Out, Details Determine Quality

Surface Treatment: Utilizing mechanical polishing and acid pickling passivation processes, the pipe surface is smooth as a mirror, with an Ra value ≤0.8μm, effectively reducing media flow resistance and improving corrosion resistance.

Packaging Protection: Wrapped in blue moisture-proof packaging cloth, clearly marked with production batch, material specifications, and dimensional information, ensuring no scratches or rust during transportation.

Quality Traceability: Each pipe comes with a material testing report, non-destructive testing report, and dimensional inspection records, achieving full traceability from raw materials to finished products.

Application Scenarios: From “Land” to “Sea,” the Ubiquitous Lifeline of Industry

Walmi Stainless Steel Seamless Pipes are widely used in:

Oil & Gas: Oil and gas pipelines, wellhead equipment;

Chemical Industry: Reactors, heat exchangers, storage tanks;

Food & Pharmaceutical: Aseptic pipelines, fermentation tanks, pharmaceutical equipment;

Marine Engineering: Offshore platforms, ship pipelines, seawater desalination equipment;

Architectural Decoration: High-end curtain walls, handrails, landscape sculptures.

Choose Walmi, Choose Trust. Wenzhou Walmi Stainless Steel Co., Ltd. has been deeply involved in the stainless steel seamless pipe industry for over ten years, possessing advanced production equipment, a strict quality management system, and a professional technical team. With the philosophy of “Quality as the Foundation, Customer as the Core,” we provide customized solutions to global clients, helping their projects operate efficiently and safely.

Contact us today to begin your industrial pipeline upgrade journey!