Wenzhou Walmi stainless steel corrugated tubes(Stainless steel bellows): The “Energy Engine” of High-Efficiency Heat Exchangers

—Reconstructing New Standards for Industrial Heat Transfer with Corrugated Technology

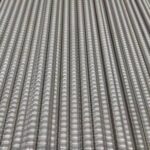

In industries such as petrochemicals, pharmaceutical fermentation, and power energy, heat exchangers are core equipment, and their efficiency directly determines production energy consumption and costs. Wenzhou Walmi Stainless Steel Co., Ltd.’s stainless steel corrugated tubes(Stainless steel bellows), with their unique corrugated structure design, are redefining the efficiency boundaries of industrial heat exchange. This article, combined with three real-life images of the core product, deeply analyzes the technological secrets and commercial value of this innovative product.

- Corrugated Gene: From Structural Innovation to Performance Leap

As seen in the real-life images, the surface of Walmi stainless steel corrugated tubes(Stainless steel bellows) exhibits a regular sinusoidal corrugated structure. This “corrugation” is not merely decorative, but a patented design optimized through fluid dynamics simulation. The spacing and depth of each corrugation are precisely calculated. With a surface roughness of 0.394 micrometers (measured data), the fluid flowing inside the tube can form a more stable turbulent layer, increasing the heat transfer coefficient by more than 30%. Compared to traditional smooth tubes, corrugated tubes can increase the heat exchange area by 25% within the same volume. Simultaneously, the elastic deformation capability of the corrugations can absorb thermal expansion stress, avoiding vibration fatigue cracks common in shell-and-tube heat exchangers.

- Industrial-Grade Reliability: A Corrosion-Resistant and Pressure-Resistant “All-Scenario Warrior”

In terms of materials, Walmi selects 316L medical-grade stainless steel, exhibiting excellent corrosion resistance in corrosive media such as sulfuric acid and chloride ions. Surface roughness measurement in the actual photos shows that the tube surface undergoes dual treatment of mechanical polishing and electrochemical polishing, with the Ra value stably controlled below 0.4μm, far below the industry standard. This ultra-smooth surface not only reduces fluid resistance but also inhibits fouling deposition, reducing the long-term operating efficiency degradation rate of the heat exchanger to less than 5%. In high-temperature and high-pressure scenarios, the corrugated structure of the corrugated tube can withstand 2.5 times the axial compressive force of conventional pipes, ensuring safe operation under extreme conditions such as steam condensation and heat transfer oil circulation.

III. Scenario-Based Applications: From Heat Exchange to System Optimization

In a practical application at a chemical group, the use of Walmi corrugated tube heat exchangers increased the thermal efficiency of a methanol distillation tower by 22%, saving over 3 million yuan in steam costs annually. Its unique flexible compensation capability of the corrugated structure allows for a 50% reduction in expansion joint configurations in pipeline system design, lowering installation costs. In vibration control, the corrugated tube, as a flexible connector in an engine exhaust system, successfully reduced the noise of a ship’s power system to below 85 decibels. More notably, its modular design supports multiple connection methods, including flanges, welding, and quick couplings, adapting to the full range of needs from laboratory pilot tests to large-scale production plants.

- Quality Visualization: A Transparent Link from Production to Testing

The handheld measurement scene in the three real-life photos is a microcosm of Walmi’s quality control system. Each corrugated tube undergoes three rigorous checks before leaving the factory: corrugation parameter verification by a coordinate measuring machine, material composition analysis by a spectrometer, and pressure resistance testing on a hydrostatic testing bench. This “traceable quality language” allows customers to predict performance during the selection process using quantitative indicators such as surface roughness values and corrugation parameters, truly achieving “what you measure is what you get” trust building.

Conclusion: As dual-carbon goals drive industrial energy-saving transformation, Walmi stainless steel corrugated tubes(Stainless steel bellows), with their 0.394-micron surface precision, patented corrugated structure, and all-scenario adaptability, are becoming a “standard component” for heat exchanger upgrades. We sincerely invite you to visit our Wenzhou production base to witness the transparent manufacturing process from raw material coils to finished product testing, and experience a truly “born for efficiency” industrial-grade solution.