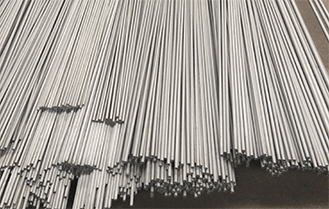

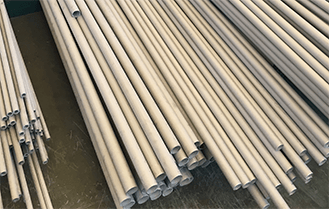

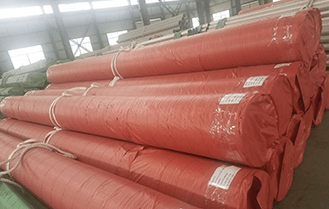

Duplex Stainless Steel Seamless Pipe & Tube

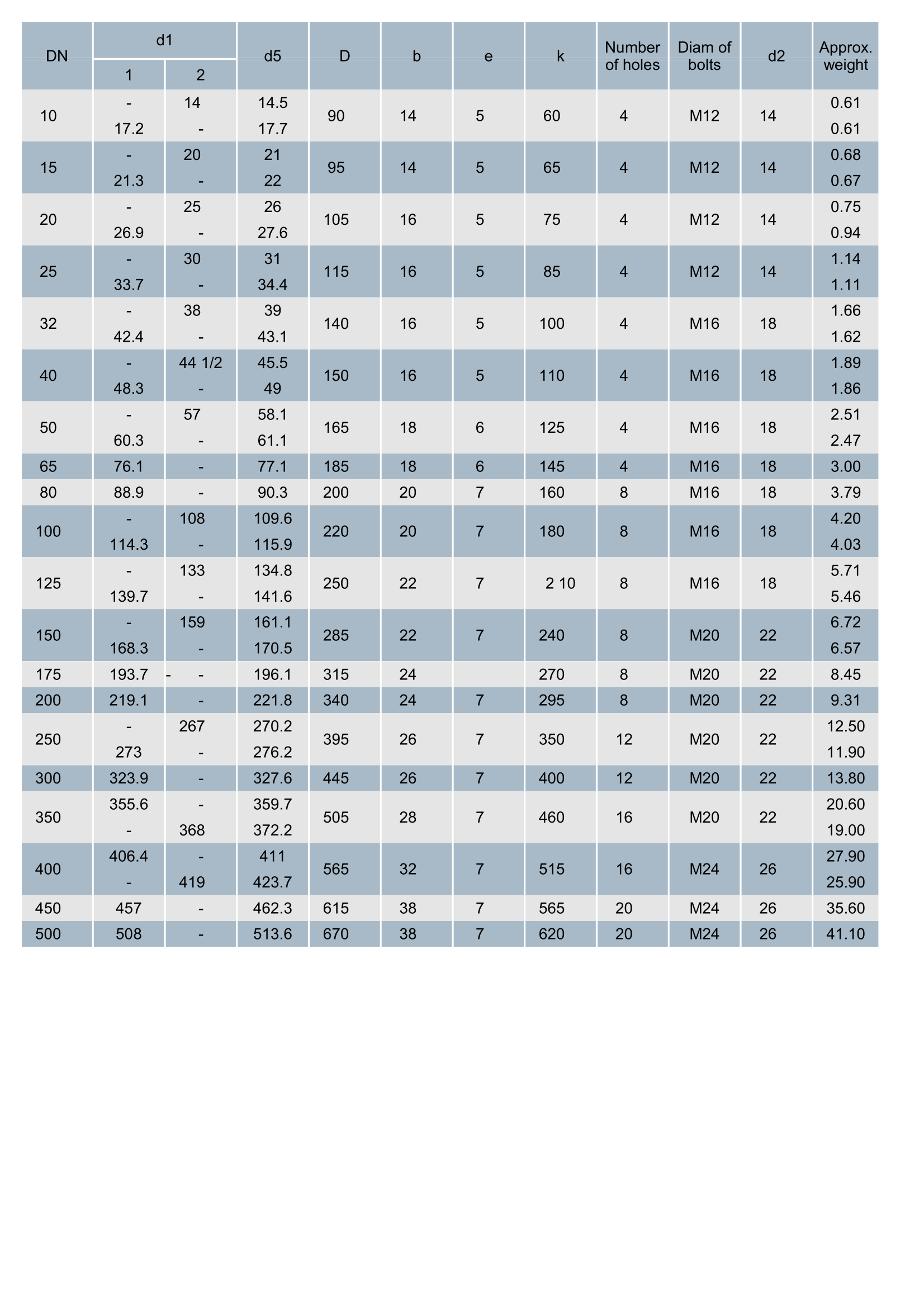

Walmi is a manufacturer of duplex stainless steel seamless pipe & tube as per ASTM A790 and ASTM A789, including materials of UNS S31803 and UNS S32205.

Sizes range from 12mm to 323.9mm ( NPS 1/4-DN8 to NPS 12”-DN300) outside diameter with pipes schedules ranging from sch10s through sch160.

The duplex stainless pipes and tubes are delivered in 5.0m-8.0m random lengths or cut to fixed lengths. All pipes and tubes can be cut to customer’s exact requirements.

Duplex Stainless Steel Seamless Pipe and Tube

Cutting & Polishing Service

S31803/S32205 Fully stock and Fast delivery

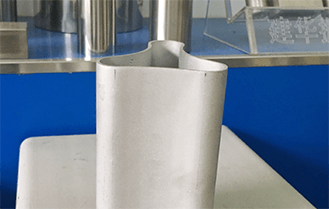

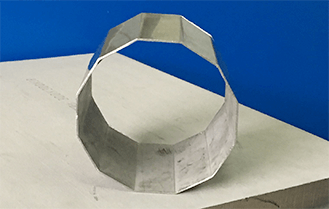

U-Bending/Bending Service

DUPLEX STAINLESS PIPE&TUBE GRADES

UNS S31803/ S32205 according to ASTM A790/ASME SA790

UNS S31803/ S32205 according to ASTM A789/ASME SA789

DUPLEX STAINLESS PIPE&TUBE CHEMICAL

Normal Chemical Composition to ASTM A790

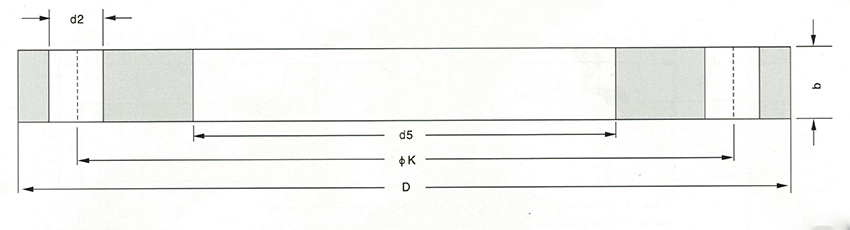

DUPLEX STAINLESS PIPE&TUBE SIZES

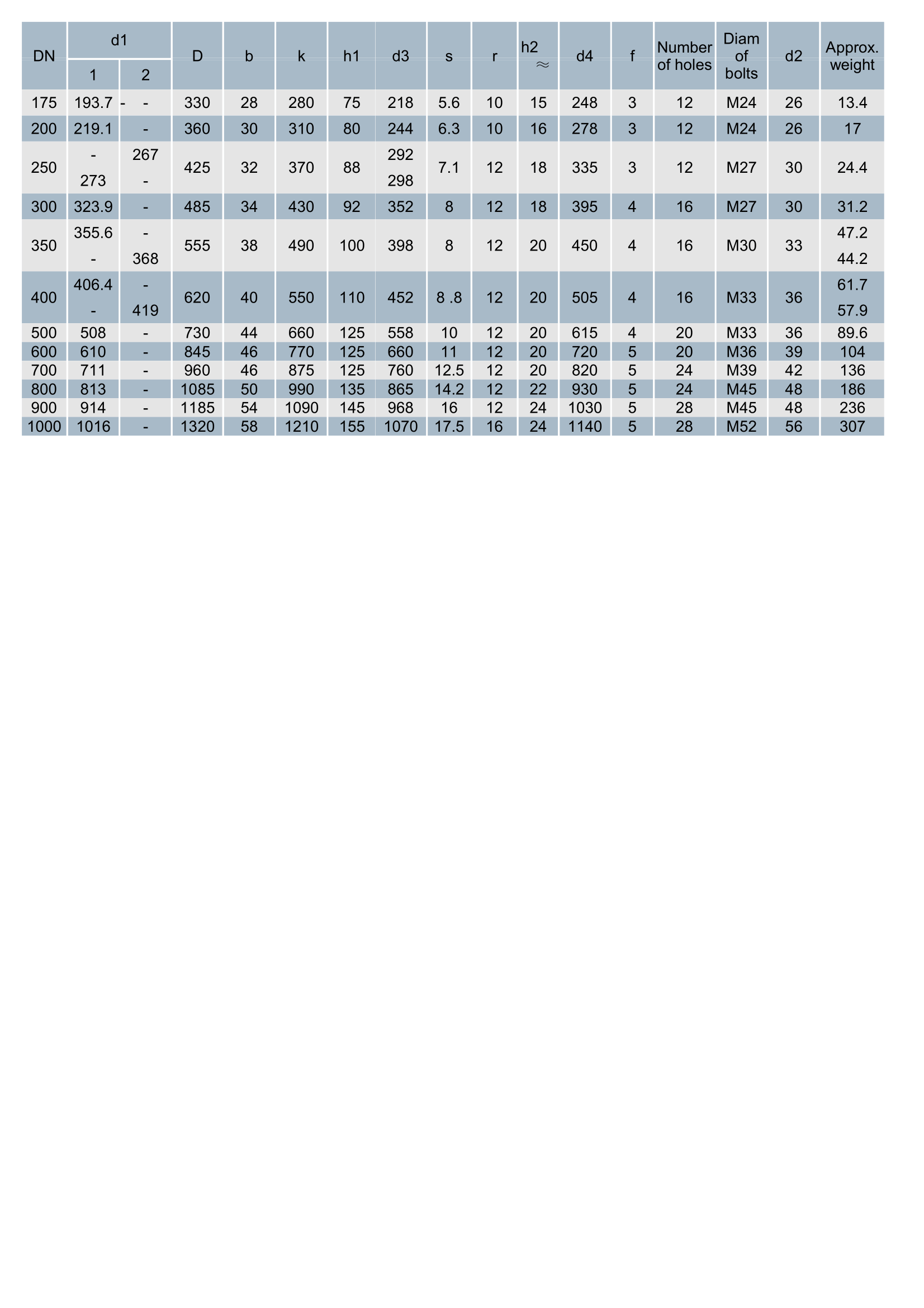

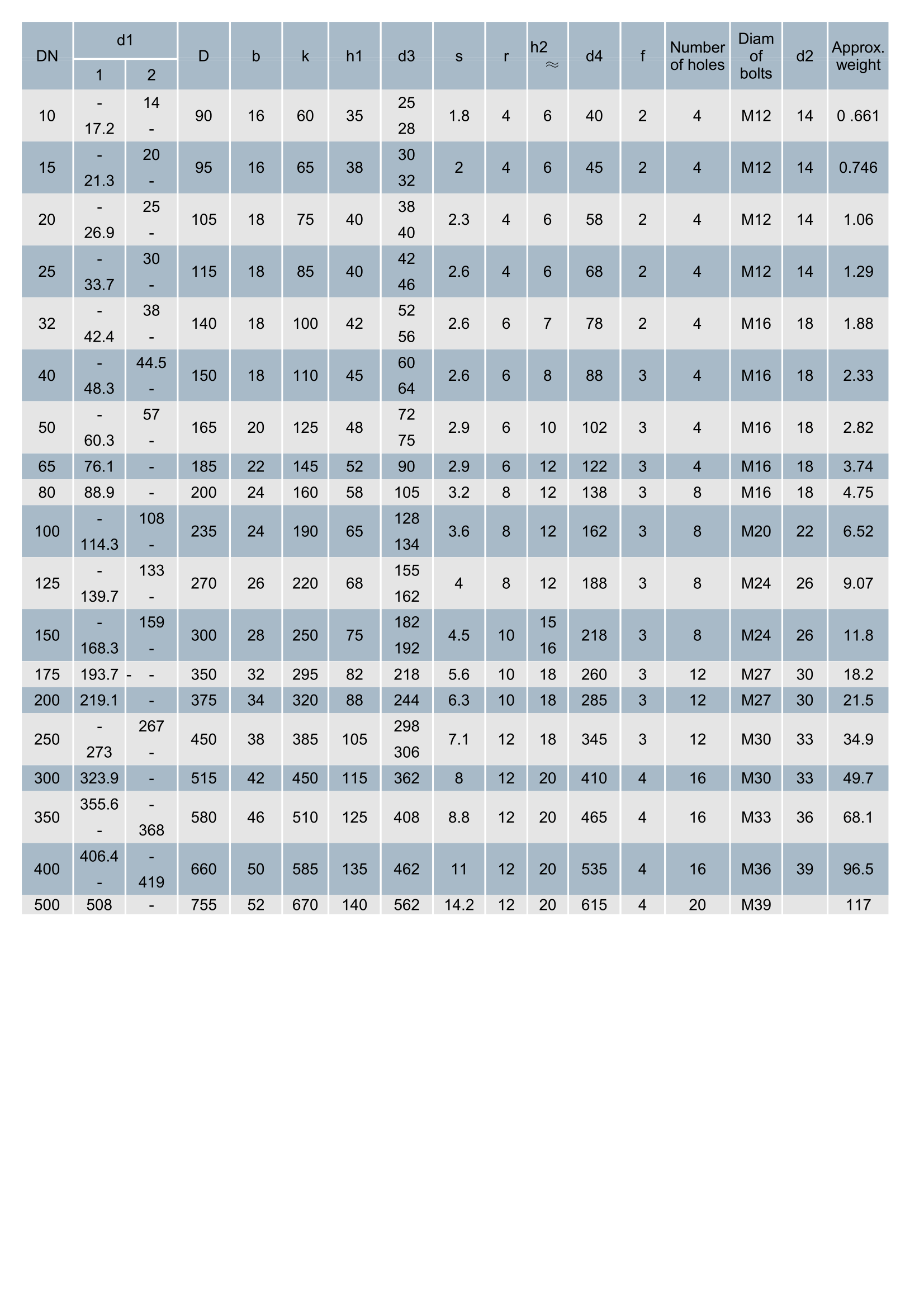

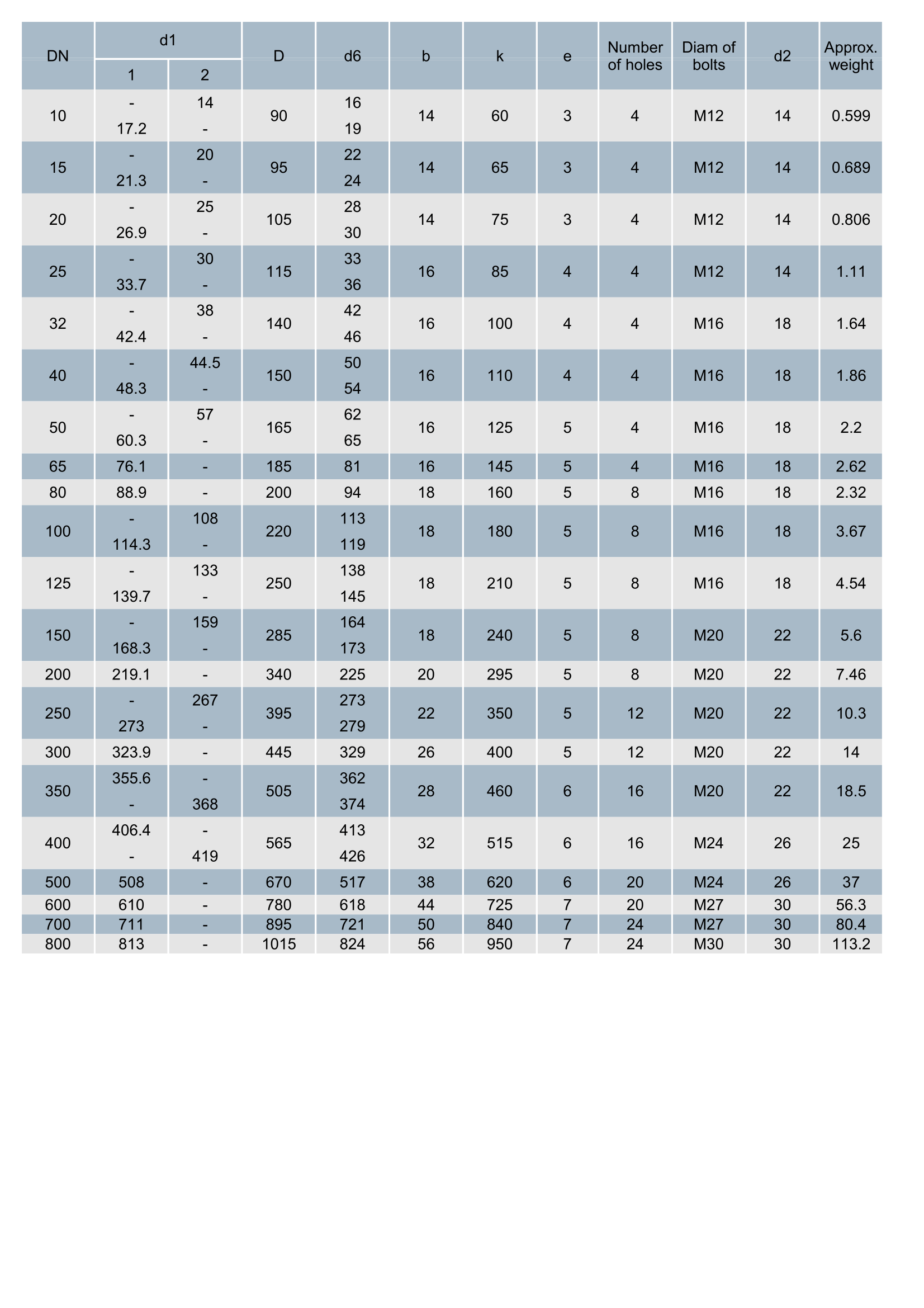

ANSI/ASME B36.19

ANSI/ASME B36.10

Walmi Duplex Stainless Steel Seamless pipe and tube compliance to standards below:

ASTM A789

ASME SA789

ASTM A790

ASME SA789

MTC: EN10204:2004 3.1

DELIVERY CONDITION

Cold Drawing/Rolling, Seamless

Solution Heat Treat & Water Quench

PRODUCTION PROCESS

Round Bar > Pipe blank > Cold Drawing

> NDT Testing > Mechanical Testing

TOLERANCE

Outside Diameter, Wall Thickness, Length of

ASTM A790 Pipe according to ASTM A999

Outside Diameter, Wall Thickness, Length of

duplex stainless pipe according to ASTM A789

MECHANICAL PROPERTIES

Intergranular Corrosion Test according

to ASTM G-48 Method A

WORKING PRESSURE

The maximum allowable working pressure for seamless stainless steel tubes at room temperature, can be calculated by the following formula:

OD=Outside Diameter (mm) WT=Wall Thickness (mm)

200 * 12 * WT/OD

For example: tube 60.3 *2.77mm

Max. allowable working pressure

= 200 * 12 * 2.77/60.3

=110 kg/cm2

All of Walmi duplex stainless steel seamless pipes and tubes are of the highest standard and will exceed all standard requirements without a shadow of a doubt.

Walmi Stainless Steel Hollow Bar are used extensively in the industries of Chemical, Petrochemical, Power, Automotive, Marine, Subsea, Offshore, Manufacturing, Pulp and Paper Processing, Food and Beverage processing, Dairy, Dying Industry, Architectural, Textile, Transport Industry, Hardware and Kitchenware Industry and many more.

The stainless hollow bar applications in the specific products can be found in the following:

Valves and actuators

Flow meters / Valves / Strainers / Baskets /

Samplers Pumps and compressors

Vacuum equipment / Hydraulic cylinders / Pump bodies Compression bodies

Axles and shafts

Rollers / Guides / Bushes / Shafts / Collars / Hubs / Bearings

Mechanical seals

Seals / Spacers / Rings

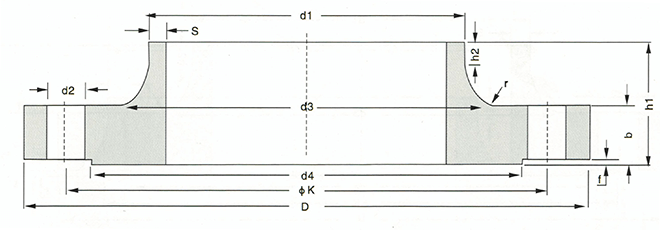

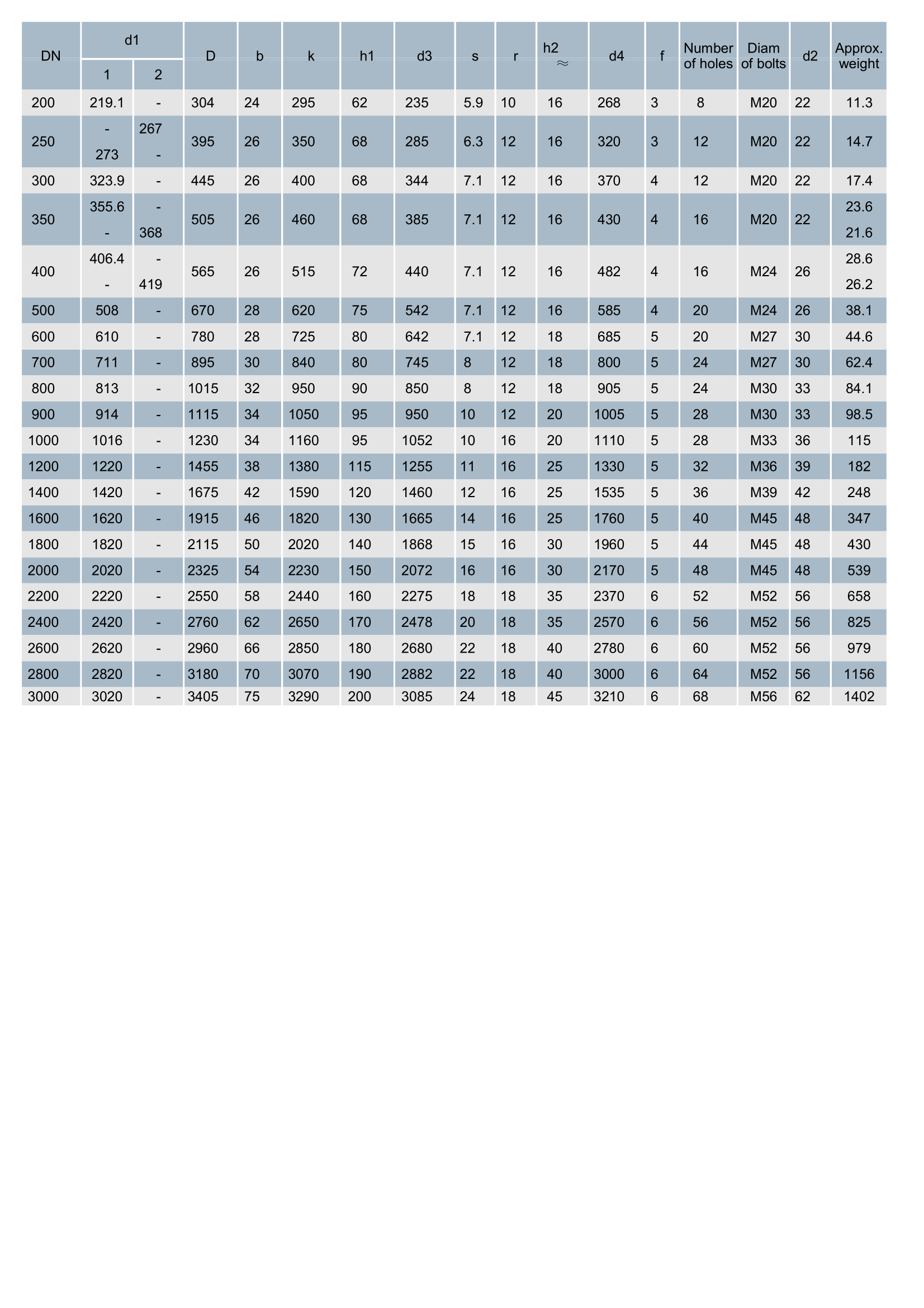

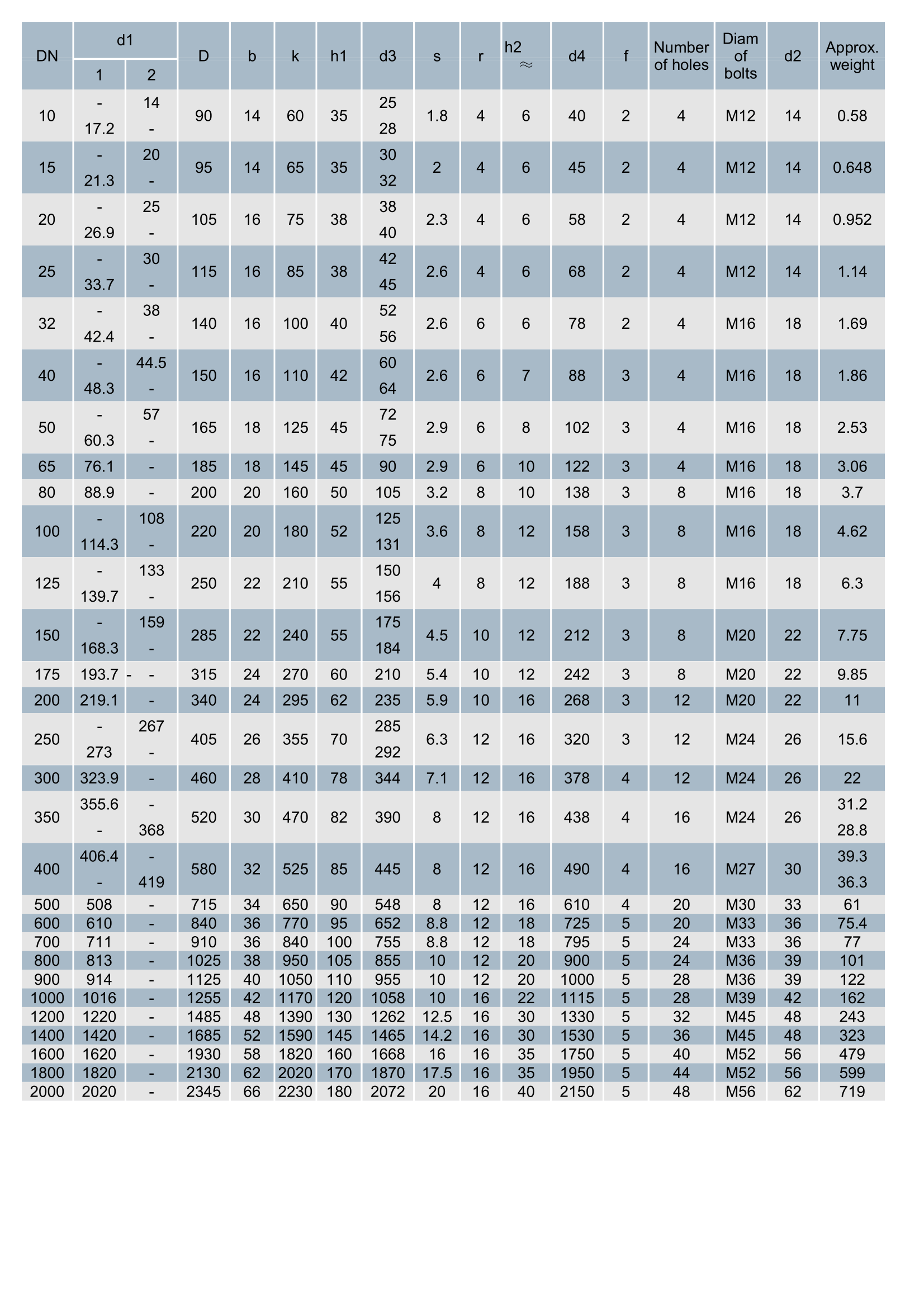

Connection assembly

Fittings / Flanges / Couplings / Connectors

Instrumentation

Sensors / Solenoids / Resistors

Agitation

Stirres / Agitators / Mixers / Blenders / Bottle filling machinery Refridgerators / Butchering / Mincers

Others

Wind mills / Watches

One-stop service for industrial stainless steel piping products, including pipes, tubes, Butt-Welding Fittings, Forged Flanges and Valves.

Value-added service are available in the following:

♦ U-bending

♦ Polishing

♦ Beveling

♦ Cutting

♦ De-burring

♦ Color Coding

♦ Marking/Tagging

♦ Welded with Flanges & Fittings

♦ Stocking for fast delivery

♦ Customized production for hard-to-source grades and sizes.

Stainless Steel Hollow Bar is primarily used for the manufacture of radially machined components, a great variety of hollow products and cylindrical components, which will be used in conditions where where corrosion is an issue .The use of Hollow Bar is an economic and efficient means of supplying high quality raw material and a sensible alternative to the use of solid bar as it reduces machining requirements and minimizes material wastage.

Advantages

Specifications:

- Excellent availability, Reduced customer inventories.

- No minimum order, 1 piece stainless steel hollow bar order is accepted by Walmi Stainless Steel.

- Improved cutting speeds and feed rates, better machine utilization and reduced fixed cost per produced stainless steel component.

- Reduced tool wear, lower lubricant usage and machinery maintenance costs, better machine utilization through reduced stoppage time.

- Less machine setting-up time and and machine cycle times, lower labor and overhead costs for each stainless component.

- Faster machining, shorter production time due to excellent and consistent machining properties of stainless steel.

- Easier handling due to lower weight per un-machined component of the hollow bar.

- Very competitive from short to long series production of hollow bar compared to forging.

- shorter production time for hollow bar compared to bore out solid stainless steel bar.

- tangled chips can be avoided Due to limited internal machining