Exploring the Industrial Beauty of Stainless Steel Tube Sheets

In the vast field of industrial manufacturing, stainless steel tube sheets, as key components, are widely used in various heat exchangers and pressure vessels, playing a vital role. Today, through several valuable images, we’ll delve into the world of stainless steel tube sheets and learn about their manufacturing, applications, and the aesthetic craftsmanship behind them.

I. Basic Concepts of Stainless Steel Tube Sheets

As the name suggests, a stainless steel tube sheet is a sheet of stainless steel with a large number of regularly arranged holes. These holes are used to insert and secure heat exchange tubes, separating the fluid inside and outside the tubes and enabling efficient heat transfer. Stainless steel tube sheets, with their excellent corrosion resistance and high strength, are the material of choice for industries such as chemical, petroleum, pharmaceutical, and food processing.

II. The Beauty of Exquisite Manufacturing Processes

The images provided illustrate the meticulous manufacturing process of stainless steel tube sheets. First, the tube sheet undergoes a precise drilling process to ensure that each hole meets extremely precise requirements for diameter, position, and spacing. This step is crucial for the subsequent installation of heat exchange tubes and the overall performance of the equipment. Next, the tubesheet surface may be polished or frosted to improve its corrosion resistance and aesthetics. The resulting mirror-smooth surface is not only easy to clean, but also effectively reduces fluid resistance and improves heat transfer efficiency.

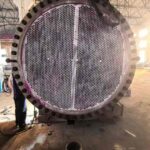

Figure 1 shows a large tubesheet, intended for use in a large heat exchanger or pressure vessel. The neatly arranged holes on its surface, along with the bolt holes along its edges, indicate that it will be tightly connected to other components, forming a complete system. This large-scale manufacturing process reflects the scale and standardization of industrial production.

III. Diverse Application Scenarios

Stainless steel tubesheets have a wide range of applications. In the chemical industry, they are commonly used in equipment such as reactors, condensers, and evaporators, where they withstand a variety of corrosive media. In the oil and gas industry, tubesheets are used in critical locations such as well strings and subsea pipelines, ensuring stable operation in extreme environments.

Figures 2 and 3 show tubesheets at different angles and stacking arrangements. These tubesheets may be used in heat exchangers of varying sizes and capacities, and are customized to meet specific needs. Whether it’s large-scale industrial equipment or small precision instruments, stainless steel tube sheets, with their excellent performance, can meet the demands of a variety of complex working conditions.

IV. The Aesthetics of Craftsmanship

Beyond practical functionality, stainless steel tube sheets also exhibit a unique aesthetic of craftsmanship. The regularly arranged holes, like a meticulously designed pattern, embody the precision of industrial manufacturing while imbuing the tube sheet with a sense of order and rhythmic beauty. Under the light, the polished surface gleams with a metallic luster, resembling a work of art.

V. Conclusion

As a critical component in industrial manufacturing, stainless steel tube sheets, with their excellent performance and wide range of applications, have become an indispensable part of modern industry. Through today’s sharing, we not only learned about the basic concepts and manufacturing processes of stainless steel tube sheets, but also appreciated the aesthetics of craftsmanship behind them. We hope these images and text will spark your interest and curiosity in industrial manufacturing and inspire you to pay closer attention to the seemingly ordinary yet ingenious industrial products around you.