Polished Stainless Steel Seamless Tubes: The Charm of Mechanical Polishing, Bright Annealing, and Electrolytic Polishing

In modern industry, stainless steel seamless tubes are widely used in petroleum, chemical, medical, and food processing fields due to their excellent corrosion resistance, high strength, and good processing performance. Polished stainless steel seamless tubes, with their exquisite appearance and superior performance, have become the preferred choice for many demanding applications. Today, let’s delve into several types of polished stainless steel seamless tubes produced by Wenzhou Walmi Stainless Steel Co., Ltd., including mechanically polished tubes, brightly annealed tubes, and electrolytically polished tubes.

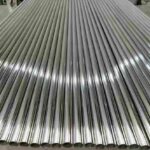

Mechanically Polished Tubes: Precise Grinding, Presenting a Basic Gloss

Mechanical polishing is the most common method for polishing stainless steel seamless tubes, as seen in the pictures of mechanically polished stainless steel seamless tubes. It uses physical friction, employing tools such as grinding wheels and abrasive belts of different grits to grind the surface of the tube. Mechanical polishing can be divided into different stages such as rough polishing, medium polishing, and fine polishing, gradually removing the oxide layer, scratches, and rough parts from the tube surface, achieving a certain degree of smoothness.

The advantages of mechanically polished tubes lie in their relatively simple process, low cost, and ability to quickly treat the surface of pipes, making them suitable for general industrial applications where surface finish requirements are not extremely high. For example, mechanically polished tubes can effectively meet the needs of structural support components or fluid transport pipelines where aesthetics are not critical. Furthermore, the polishing precision can be adjusted to suit different requirements, achieving finishes from matte to semi-gloss and even near-mirror surfaces.

Bright Annealed Tubes: A Combination of Heat Treatment and Aesthetics

Bright annealing is a process that combines heat treatment and surface treatment. During the production of seamless stainless steel tubes, the tubes after cold working contain internal stress, and the surface may have some oxidation and roughness. Bright annealing involves heating and slowly cooling the tube in a protective atmosphere (such as hydrogen or nitrogen). During this process, the protective atmosphere prevents surface oxidation, while the heat treatment eliminates internal stress and improves the tube’s mechanical properties.

Stainless steel seamless tubes that have undergone bright annealing exhibit a uniform silvery-white luster, making them very aesthetically pleasing. Furthermore, the elimination of internal stress improves the toughness and ductility of the tube, making it more suitable for subsequent processing and forming. Bright annealed tubes have wide applications in fields with high requirements for tube performance and appearance, such as high-end decoration and precision instrument manufacturing.

Electropolished Tubes: The Magical Effects of Electrochemistry

Electropolishing is a surface treatment method that utilizes electrochemical principles. A seamless stainless steel tube is used as the anode and placed in a specific electrolyte. By applying an electric current, the microscopic protrusions on the tube surface are preferentially dissolved, achieving a smooth and bright finish.

The most significant characteristic of electropolished tubes is their ability to achieve extremely high surface smoothness, even reaching a mirror-like effect. Moreover, electropolishing can remove microscopic cracks and defects on the tube surface, improving its corrosion resistance. In industries with extremely high hygiene requirements, such as food processing and pharmaceuticals, electropolished tubes are an ideal choice due to their smooth surface and resistance to bacterial growth. Simultaneously, the high-precision surface finish of electropolished tubes also plays an important role in fields such as optical instruments and semiconductor manufacturing.

Wenzhou Walmi Stainless Steel Co., Ltd. boasts extensive experience and advanced technology in the production of seamless stainless steel tubes and polished pipes. Whether it’s the economical and practical mechanically polished pipes, the performance-and-aesthetics combination of bright annealed pipes, or the high precision and corrosion resistance of electrolytically polished pipes, we can meet the diverse needs of different customers. With the continuous development of industrial technology, the application prospects of seamless stainless steel tubes and polished pipes will be even broader, and Walmi Stainless Steel will continue to provide high-quality products and services to various industries.

-150x150.jpg)