Socket Weld Flange ANSI/ASME

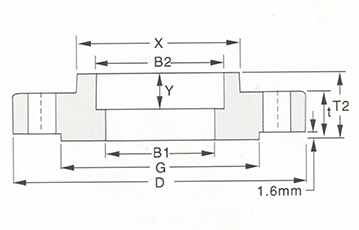

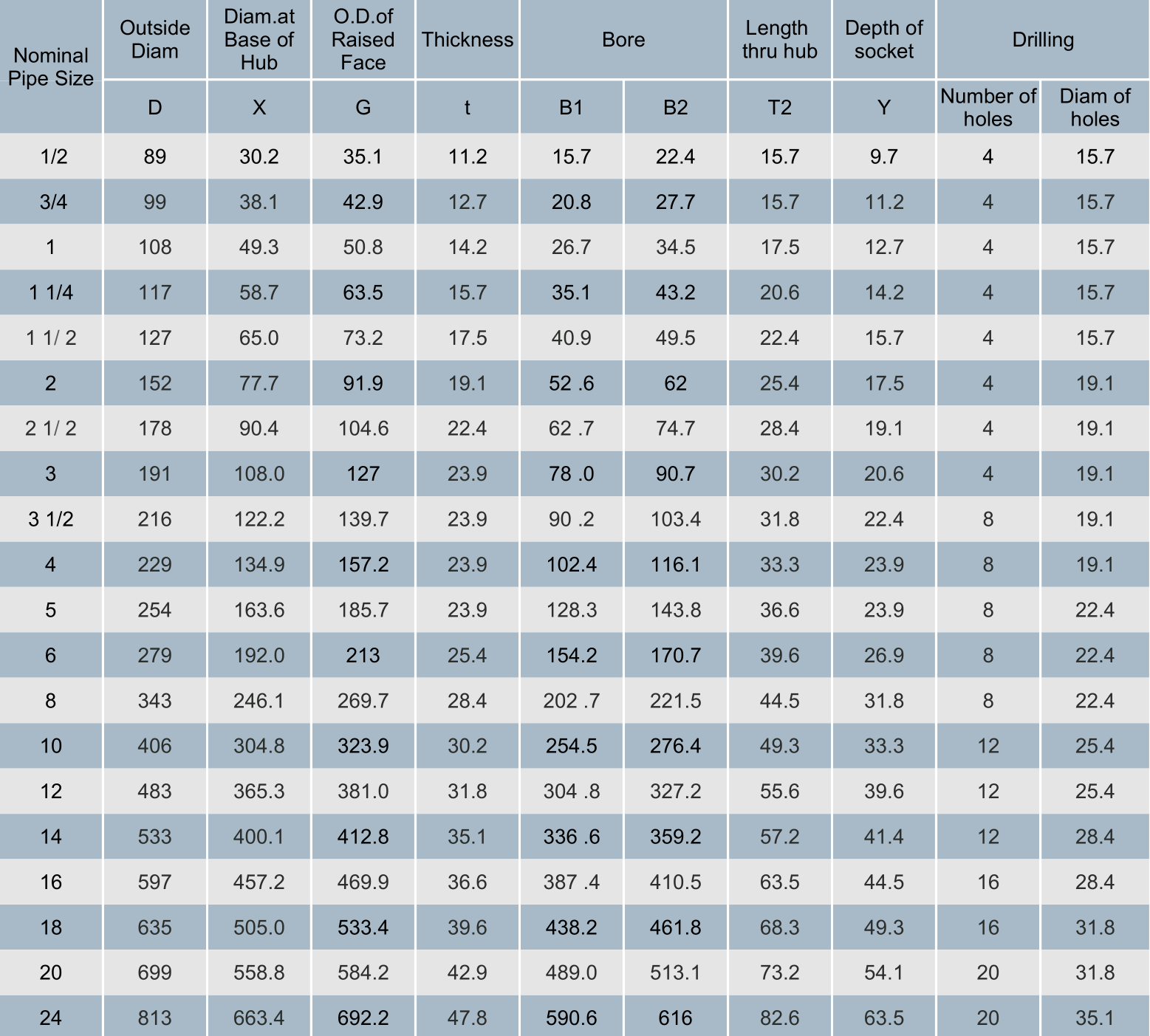

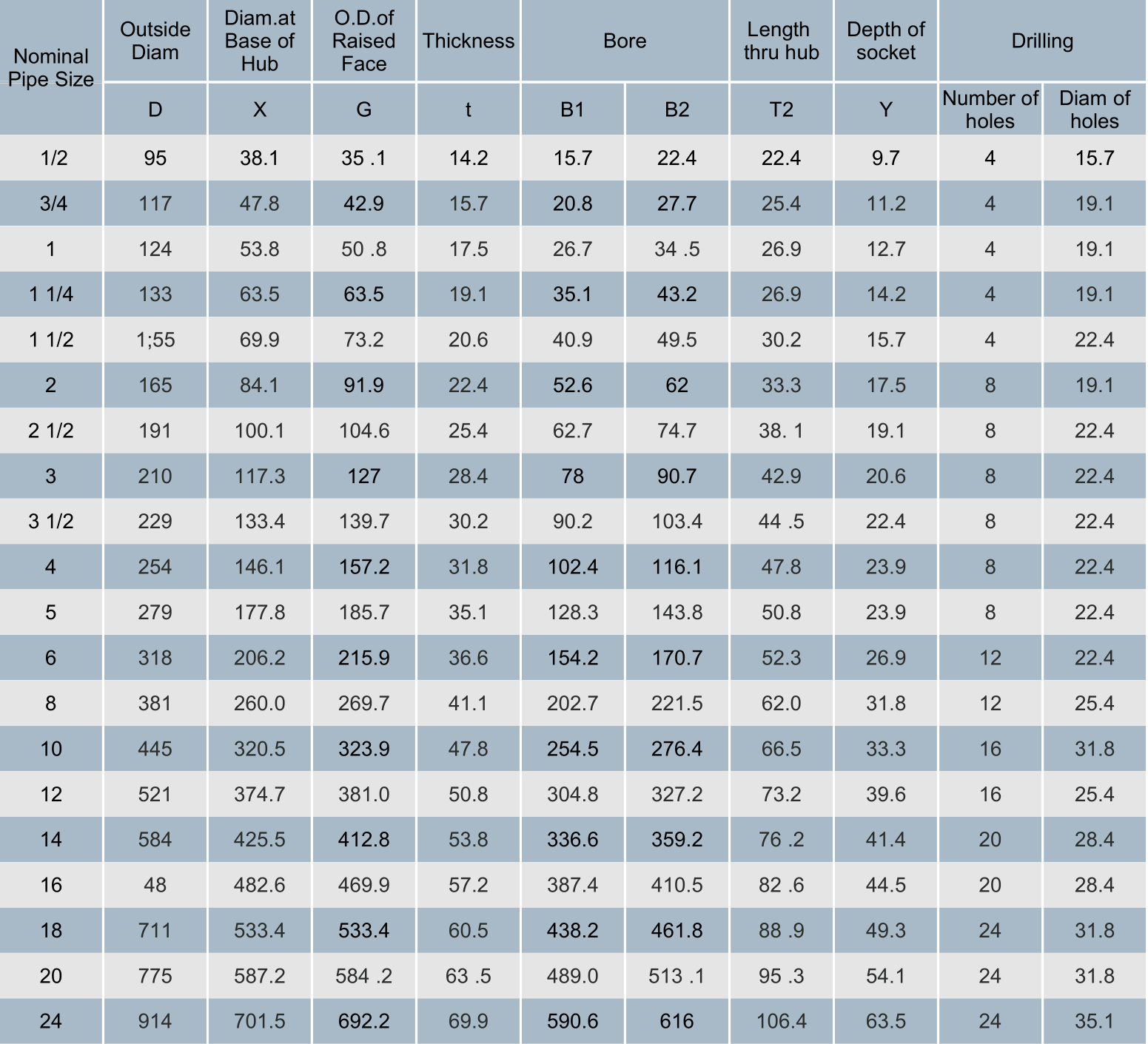

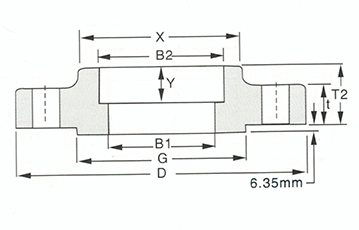

Walmi manufacturer socket weld flange as per ANSI/ASME B16.5, which has a counter-bore and a smaller bore. The counter-bore is fractionally larger than the outside diameter of pipe which it is to be fitted, so the pipe can be inserted into the socket end of the flange and be connected by fillet weld around the hub. The smaller bore is same with the inside diameter of the pipe which it is to be fitted, so the pipe can sit on it.

Walmi typically supply socket weld flange with a raised face (RF), flat face (FF) or Ring Type Joint (RTJ) face. The standard raised face height is 1.6mm (1/16″) for socket welding pipe flanges under 400#, 6.35mm(1/4″) for 400# and up. The raised face socket welding flanges have to be welded to the pipes.

The different bore sizes of socket weld flanges allows for a smooth bore and better flow of the fluid or gas inside of the pipe. But both the dimensions and applications of socket welding flanges are similar with slip-on flanges, which are widely used in petrochemical, food and pharmaceutical industries.

SPECIFICATION

- Forged stainless steel material conforms to ASTM A182/ASME SA182, including austenitic stainless steels F304/304L,F316/316L,F321,F347,F310S; duplex stainless steels S31803/S32205/S2205; super-duplex stainless steels F32507 / UNS S32750/S2507.

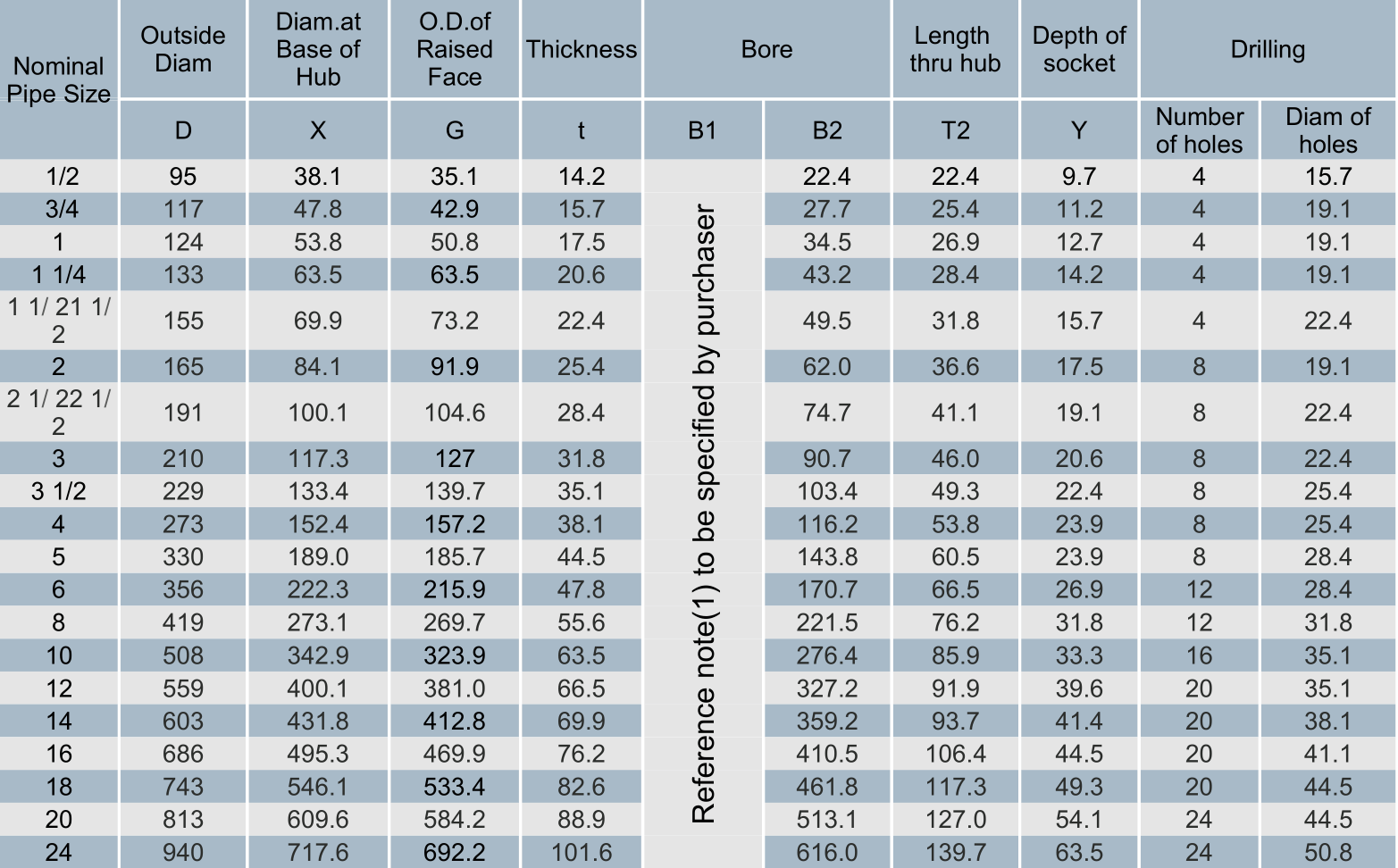

- Dimensions conform to ANSI/ASME B16.5

- NPT Threads conform to ASME B1.20.1

- Up to 24″ Listed- Larger sizes available

- Customized or bespoke flanges of customer drawing are available.

- Certified to EN 10204/3.1.

Related Products: B16.47 flanges | EN /DIN Flanges | Pipes | Fittings | Valves